About Us

Established in 1991, Computool Pty. Ltd. is a company with over 30 years of proven and refined manufacturing methods.

Computool has been the preferred supplier of toolmaking services and supply of complex and unusual parts for many industries

including; medical, defence, security, electronic, petrochemical, pharmaceutical, automotive, cosmetics and packaging.

We are committed to providing quality workmanship and precision engineering services to industry in an accurate, dependable and timely manner.

Injection mould tooling however, is our expertise.

We’ve produced many moulds that have demanded innovative solutions, including things like:

- balanced family moulds

- unscrewing cores

- complex shut-offs

- hot-runner moulds

- interchangeable cores & cavities

- double 1/2 moulds

- collapsible cores

- unusual ejection mechanisms

The

Where do plastic parts come from, how they are made? What is the best way bring an idea to life? If you have other questions we’ll can answer those too!

What is a toolmaker?

A toolmaker is a highly skilled craftsman who uses several complex machines to make a mould, a presstool, to form the required component – plastic or metal.

Toolmakers also are precision machinists who can make practically anything from a drawing or a computer model.

They take great care with their work as the tiniest error can badly effect the end result of tool or component. An Injection Mould, or other device is also called a tool, hence the name toolmaker.

What are the basic steps to mould a plastic part?

First, a computer model will be made which will form the central element in a mould design. Secondly, the mould design will take shape around the ‘part’. We need to determine if the mould will require extra moving components (like sliders or unscrewing) or the mould will simply ‘open and shut’ to release the plastic moulded part. Once the mould is ready, we will inject the first few parts to see how the part moulds and what sizes need to be adjusted.

Can I get my idea for a plastic part 3d Printed?

Before a 3D print can be made, a computer ‘solid’ model is required which provides the data needed for the printer. Once we have the ‘solid’ model, we can print a part and assess any changes needed. Sometimes customers have designed their own ‘solid’ model in a ‘step’ format and this is a good beginning. However, often the model is not of high quality and this will need to be remedied before a quality print can be made.

How do plastic parts get made?

All mass-produced plastic parts are made in some kind of mould. It may be an injection mould (most intricate shapes), an extrusion mould (long sections like tube and channel), a blow mould (bottles), a vacuum mould (large thin parts) or rotational mould (water tanks)

How long does it take to make an injection moulded part?

Depending on the complexity, a basic mould will take from 2 weeks to over 8 weeks to begin producing the first plastic parts.

How much does it cost to make a plastic part?

For a very basic and small part you could spend about $3,000. For a complex or multi-cavity mould made to run fast and for a very long time, from $20k to over $40,000.

What if I just want a few parts?

We can make a low-cost prototype mould that will easily make several hundred parts. Or for just a few, they could be machined from solid plastic or 3D printed. 3D printing requires a computer model which is often a higher cost than the printed parts. Machining the few parts may be a lot cheaper.

I need several different parts... do I need several moulds too?

Often they can be made in the one ‘Family Tool’. If they are similar sizes then that would be an ideal solution. There are many options in this area best determined by carefully analysing the parts required.

How much do the parts cost?

Smaller parts cost only a few cents each, especially if they are made in a multi-cavity mould. For eg, if there are 6 cavities, 6 parts are made at once. Larger parts may cost a few dollars each. The more we make, the cheaper they get.

How long does it take to mould a part?

Most parts are made in a moulding cycle of 10-20 seconds, some take much longer because of their thickness or large size…maybe even a few minutes.

What kind of plastic should I use?

There are many plastics that are suitable for all kinds of purposes. Some are especially good outside, some have a very high wearability, and others can be clear and very strong. Only a careful examination of the product and it’s intended use will help decide which plastic is the most suitable and cost effective.

Do you make a prototype before making the actual mould?

Often a computer model will suffice to ensure the part is correctly designed. However there’s nothing quite like holding a prototype in your hands and making decisions based on how it feels, and will it cope with the intended task?

Who owns the mould or tool that is made?

Usually you, the customer, will own the tool. Although, to reduce start up costs for small quantities, we can arrange a shared ownership where you would own the mould components that are explicitly used to make your plastic parts and we retain ownership of the rest of the mould for use with other moulding products.

Can I test my idea first?

A prototype can be made to enable a life-like replica of the part you have designed. This is an excellent way to ensure you have thought about all possible uses of the product and that it is well suited to the task in mind. A prototype may only cost a few hundred dollars, and is money well spent before you commit to a mould. 3D printing is also a great way to get started – we can do that too!

Can I make parts in different colours?

Practically any colour you can imagine is available. Some colours and styles are more expensive, like metalic and fluorescent. A mould can produce parts in any colour you choose – so long as the quantity for each colour is sufficient as the colours can be quite expensive and usually sold in large quantities.

Is there a cheaper way to make a plastic part?

Plastic parts can be machined from solid plastic if only a few are required. We can use solid plate, block, tube or rod, or fabricate the part from several components and weld, glue or fasten the pieces together. 3D printing is also a viable option for many products – even small production runs!

I have an idea for a plastic part... what do I do now?

The best approach is to give us a call and discuss your requirements – this will only take a few minutes. You will be advised on the next steps to take – especially if you need to protect your new idea.

We can discuss with you what tooling you would need, it’s approx. cost and the time to have a prototype made or the mouldings from a tool. We can also advise on the part design and any post moulding processes like assembly, printing or metallising etc.

I only have a rough sketch... will that be enough?

It’s a great place to start. We can work from that, and with some discussion we can develop your ideas, working from a prototype if necessary, into a fine product and design the mould at the same time.

If I get a mould made, who will make the plastic parts?

We have a long track record of supplying the ongoing parts for many customers once the mould is designed and commissioned. For many customers, they simply require the parts in a box – all the other steps are not relevant.

We take great pride in helping our customers through the complex and often unfamiliar route to getting a new product made. We know plastic tools and moulding.

How is a mould made?

Several different machines are used. Each has a particular feature not found on the others. We use CNC (Computer Numerically Controlled) milling machines, lathes, Electrical discharge machine (EDM), grinding machines to name a few. The basic process is to remove the metal from a solid block of special tool steel by very hard cutting tools. The EDM uses copper electrodes to erode the cavity for the plastic component with electrical current.

After machining is finished, there is often considerable hand work to do to polish, fit moving parts together accurately, and prepare the mould for a special heat-treatment process to ensure the mould will work smoothly for a very long time.

How many parts will a mould produce?

Potentially it could make millions if treated well and maintained. Some plastics are abrasive or chemically aggressive so the tool needs to be designed with that in mind to ensure longevity.

How does an injection mould work?

Once it is placed in the moulding machine, it is hydraulically clamped shut and plastic is injected at high pressure to ensure it flows to all parts of the cavity formed by the closed halves of the mould.

The water cooled mould remains closed while the part cools from over 200 degrees down to approx 30 degrees. Thenthe mould opens and the firmed part is ejected from the mould and falls into a box or is grasped by a robotic gripper.

Moulds can cost $1000's of dollars - why are they so expensive?

Firstly, the machines that we use are often hundreds of thousands of dollars each. Then each mould may take several weeks to produce by highly skilled craftsmen. Lastly, the materials and components we use can also be expensive. An injection mould has to be extremely accurate in order to produce, and keep producing a fine plastic component. All this takes considerable time, skill and resources.

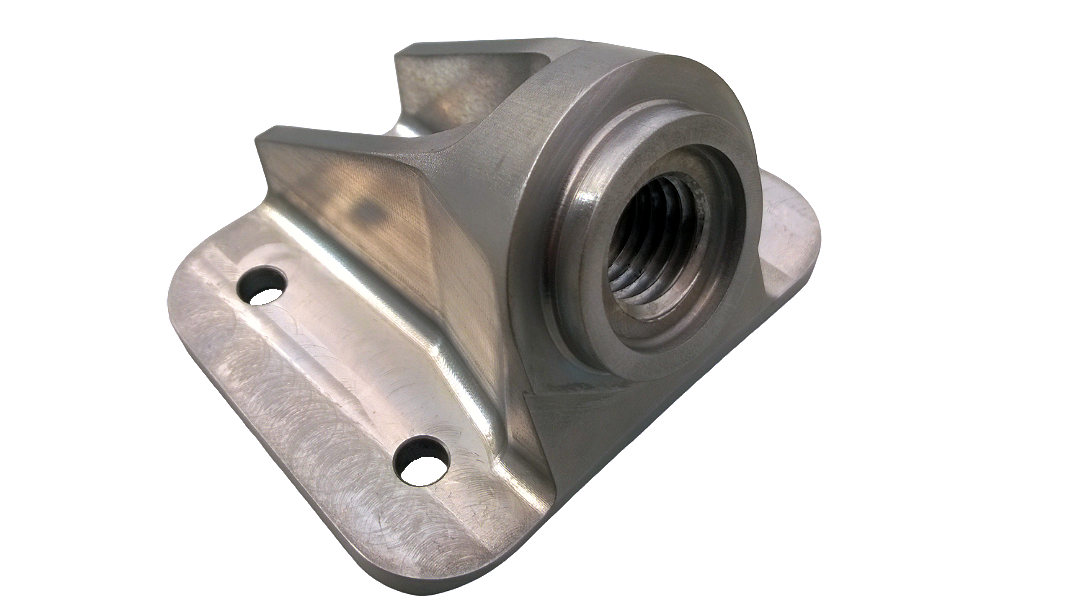

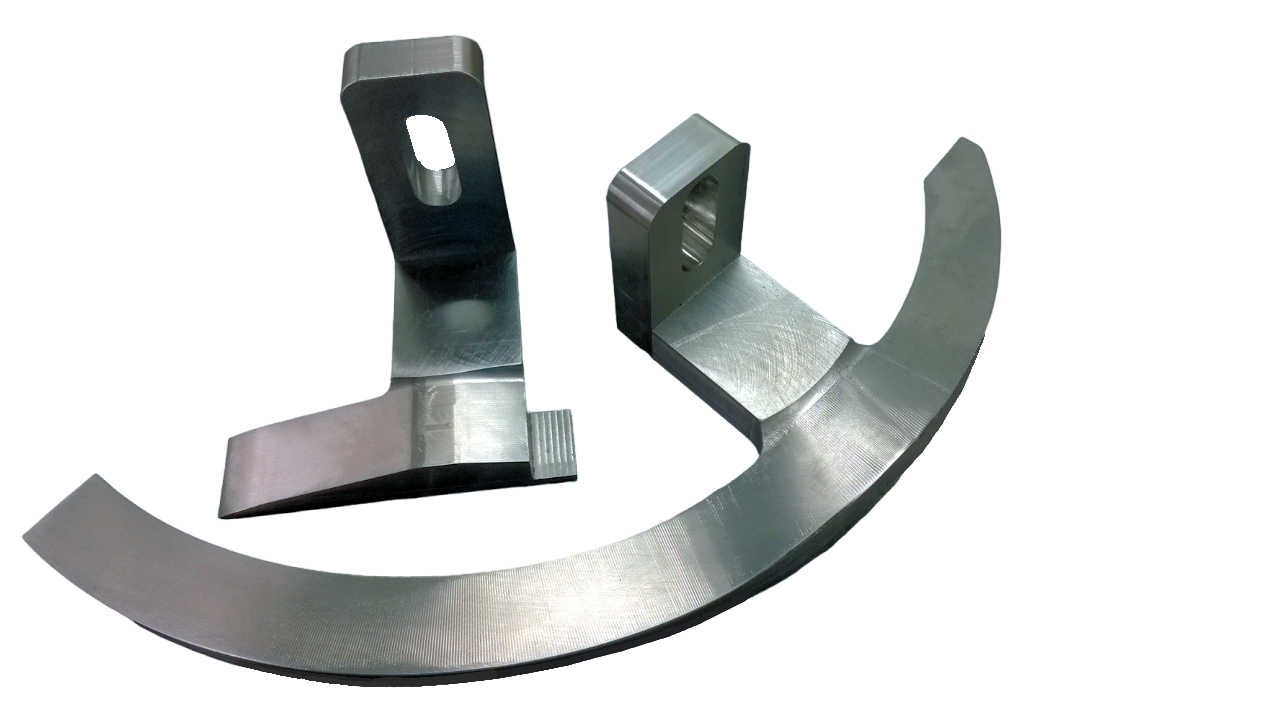

Can you make precision parts too?

With the latest software, CNC machinery and other toolroom machines we can make just about anything from all kinds of materials. We prefer smaller runs of parts even if they are complicated.

Will my mould be used for other people's orders?

This might happen in China, but not while it’s in our care! You have exclusive right to the product from your moulding tool.

Can a mould be changed once it is made?

Yes. There are many ways to alter a mould in order to change the part details. Some changes are quite simple, others can be very complex. Making prototypes first will avoid expensive changes.

How long will a moulding tool last?

– a quality mold will last for decades if maintained and treated with respect.